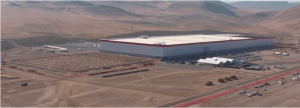

Tesla has worked hard to establish itself making high-end, luxury electric cars, now it’s got its sights set on the mainstream. That push has two main elements behind it: the Model 3 and the Gigafactory, where Tesla is looking to mass produce batteries for a lower price. Until now, details about the factory had been thin on the ground, but last week’s unveiling in Nevada finally provided some detail on the massive battery production facility.

So, why has Elon Musk bet big on a factory in the Nevada desert? Well, Tesla has high hopes for Model 3 production, aiming to churn out half a million examples of the everyman EV per year. On top of that, the company is going to need batteries for its Powerwall, Model S and Model X.

To make that all happen, the cost of battery production is going to need to come down, and the rate of production is going to need to ramp up dramatically. By taking the entire production process and dealing with it in-house, Tesla is arguing it can speed up the rate of development when new technologies come along.

Rather than relying on external suppliers to deliver updated cells and chemistry, this setup allows those updates to be delivered to customers more quickly than would otherwise be possible. It also means there’s no need to rely on current supply facilities, which simply aren’t able to keep up with demand.

“In order to make a half million cars a year, we would need every lithium-ion battery factory on earth that makes batteries for phones, laptops, car – everything – just to achieve that output. So, either we figure out somewhere to build this thing [Gigafactory], or there will not be the cars that are needed,” Musk told the crowd at the factory opening last Friday.

In two years the company is expecting to be producing 500,000 cars per year, or 50 GWh worth of batteries. Although there’s no definite timeframe, (Musk says this could happen in “2020 or thereabouts”), the factory’s full capacity is expected to be 1.5 million cars per year.

When completed, the factory will cover around 6 million sq ft (557,400 sq m), making it the largest building in the world by footprint. It will, however, be second to the Boeing plant in Seattle based on volume. Still, inside there’s enough space to house 93 Boeing 747s – or 50 billion hamsters if that’s your preferred metric.

Currently, the factory is being used purely for battery production, with vehicle production to take place at the brand’s current factory in Fremont, California. Down the track, Musk says the concept could be expanded and refined to the point where raw materials roll in one end of the factory, and completed vehicles roll out the other.

A video of Tesla’s Gigafactory opening is below.