Editor Notes : “Researchers have created a way to drastically reduce the price of large sheets of graphene by using the same type of inexpensive copper used to manufacture lithium-ion batteries.”

By Colin Jeffrey,

Since first being synthesized by Andre Geim and Kostya Novoselov at the University of Manchester in 2004, there has been an extensive effort to exploit the extraordinary properties of graphene. However the cost of graphene in comparison to more traditional electronic materials has meant that its uptake in electronic manufacturing has been slow. Now researchers at the University of Glasgow have discovered a way to create large sheets of graphene using the same type of cheap copper used to manufacture lithium-ion batteries.

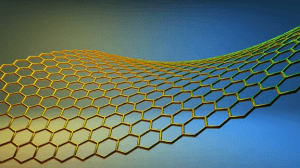

As a two-dimensional crystal of carbon atoms, graphene is a basic building block of many carbon derivatives such as zero dimensional fullerene, one dimensional carbon nanotubes, and three dimensional graphite. These carbon based nanomaterials have all been used in electronics to create everything from solar cells to light bulbs and ultrasensitive gas sensors. To produce high-quality material scaled-up for electronics on large areas, though, graphene has proved more expensive than standard electronic substrates such as silicon.

A large part of this expense is the substrate on which Graphene is generally produced. By using a process of chemical vapor deposition (CVD), graphene has often been grown as a monolayer (a layer one atom thick) by exposing platinum, nickel or titanium carbide to ethylene or benzene at high temperatures. Recent production methods have lowered these costs somewhat by incorporating copper as a substrate, but even this method can still prove expensive.

To help drastically reduce these costs, the researchers came up with the idea of depositing high-quality graphene on the surface of inexpensive copper foils often used to make the ultra-thin cathodes (negative electrodes) in lithium-ion batteries. As it turns out, the surface of the copper proved to be both completely smooth and a superior substrate on which to form the graphene.

“The commercially-available copper we used in our process retails for around one dollar per square meter, compared to around $115 for a similar amount of the copper currently used in graphene production,” said Dr Dahiya, of the University of Glasgow’s School of Engineering. “Our process produces high-quality graphene at low cost, taking us one step closer to creating affordable new electronic devices with a wide range of applications, from the smart cities of the future to mobile healthcare.”

The team believes that large-scale, inexpensive synthesis of high quality graphene films through their method could realize graphene-based flexible optoelectronic systems, including such things as cell phones with roll-up displays, e-paper, radio-frequency identification (RFID) tags, medical patches to deliver drugs or monitor vital signs, and tactile or electronic skin for robotics and prosthetics.