At a secluded test site in the Nevada desert about 10 miles north of Las Vegas, Hyperloop One today made its first public demonstration of a key component of its new transportation system that promises near supersonic speeds at ground level. The Propulsion Open Air Test (POAT) took place under sunny skies and saw electromagnets propel a sled at 115 mph (185 km/h) along a specially-built test track measuring 1,500-ft (457-m) long

According to Hyperloop One co-founder Brogan BamBrogan, the purpose of the test was not only to show potential partners how far Hyperloop technology has come in a short time, but also to act as a component test in the run-up to a full-scale test version of the system, which is expected to come online later this year.

In its fully integrated form, Hyperloop will consist of a partly-evacuated steel tube in which will run a capsule. This capsule, which will use a compressor to create a stronger vacuum ahead of the vehicle to cut down on air resistance, will include a passenger/cargo compartment, batteries to power the system, and a levitation device to lift the capsule off the guide rails.

Unlike Hyperloop Transportation Technologies, which recently demonstrated a passive maglev system, Hyperloop One uses compressed air forced through runners to create a near-frictionless surface to glide along.

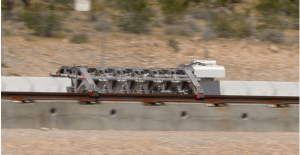

On paper, the technology is impressive, but in the real world these individual components require rigorous testing and at its Nevada facility Hyperloop One is currently developing the magnetic drive that accelerates the capsule to over 700 mph (1,126 km/h). In this case, the tube was replaced with an open-air test track, the air blades with metal slippers running on steel rails, and the capsule by the “Sandshark” test sled.

Target test engineer Jeff Ferm told us that the rail-and-slipper arrangement is one that’s been used since it was first developed for rocket sleds over 75 years ago. He added that this setup is much simpler than wheels, and adds only negligible friction to the test.

The propulsion system for the test consisted of a sled-mounted rotor and a 187-ft (57-m) long stator. Put simply, the device that catapults the sled at a force 4.3 times the pull of gravity can be thought of as an electric motor that’s been cut open and flattened out, so instead of going around, the rotor shoots off in a straight line.

Today’s demonstration was a classic blink-and-you-missed-it event that took only about four seconds. As the 10-second countdown reached zero, the sled moved forward almost silently, then shot along the rails like a stabbed rat. Then the test vehicle slammed into a barrier of sand, which exploded into a brownish-red spray as the sled ground to a halt.

In a post-demonstration briefing, BamBrogan said that when the test track stator is doubled in length, the Sandshark will reach speeds of 400 mph (644 km/h) in two seconds. However, he emphasized that just getting a sled to go fast wasn’t the goal – the purpose of the runs are to test various components and capabilities, including the Hyperloop power system, ways of making them fully controllable by means of Variable Frequency Devices (VFC), new software, and switching gear to make the propulsion system scalable for practical use and bring down per-mile costs.

As an example of this testing regime, we saw the Sandshark being retrieved from its stopping point by a robotic Sled Recovery Vehicle (SRV) – the purpose of which is entirely practical. Ferm pointed out that the engineers want to carry out as many runs per day as possible, but it isn’t safe to approach the track until it’s powered down. The SRV eliminates this and allows runs every 30 minutes.

According to BamBrogan, the next phase of the program is to build a fully-integrated Hyperloop system at the test facility by the end of the year to demonstrate that the idea is not only possible, but feasible and even practical.

BamBrogan told us that he doesn’t see Hyperloop competing directly with other transport systems, but rather enhancing them. In addition, he sees Hyperloop One not as the controller of the new Hyperloop systems of tomorrow, but as a developer and enhancer that builds an “ecosystem” that other companies, individuals, and governments can adapt as they see fit. In terms of a timeframe, he does expect Hyperloop to be fully operational within five years.

When asked what it will be like to ride in Hyperloop, he said that it will be “like an elevator” with a brief acceleration of under 2.5 g, followed by a ride without turbulence or sharp, buffeting curves.

In a previous briefing, Hyperloop One executives said that the system has a wide range of applications from intercity to intracity travel, container port management, and generally shrinking the world through high-speed, on-demand travel and freight transport.