The services that drone companies can provide to wind farm owners/operators will lead to faster, cheaper and more efficient operations and maintenance solutions, which will completely transform the O&M business.

According to Anil Nanduri, GM of Intel’s drone segment, it’s not too often that a scalable technology comes along that will transform not only how certain business processes are performed but the entire businesses themselves.

Take wind farm inspections as an example, where drones are beginning to play a role in performing inspections of wind turbine blades.

“We believe these systems can capture defects better than what human eyes can do,” said Nanduri.

Intel is working to understand the pain points of its customers who use drones for inspections, such as Aerial Media Scotland, Surefire Imaging and Texo Drone. Nanduri said those pain points range from pilot fatigue, to data transfer, to data processing

“Our focus is how can our technology — the assets we have from the servers to the connectivity as well as the algorithms we can build for making this data available faster — be helpful tools for the inspectors.”

Easing Pilot Fatigue

One company making headway on the pilot fatigue pain point is SkySpecs, which has taken the pilot all but out of the equation, said CEO Danny Ellis.

“Nobody’s flying it. No one’s controlling the camera, no one is telling it when to take a picture. The drone is making all those decisions on its own,” he said.

Solar Energy in South Carolina

More Americans are taking advantage of the substantial and various benefits installing a residential solar energy system can provide – and not just because the federal solar investment tax credit is winding down. Utilities in states across the nation are ramping up their investments in solar power generation as well, but they continue to lobby for rules and regulations that maintain the balance of market power decidedly in their favor.

SkySpecs developed an autonomous drone that has been used to inspect 54 wind farms since its launch (pun intended) in April 2017, according to Ellis.

“I think we’ve taken probably almost 750,000 pictures this year since April,” he said.

Because there are line-of-sight regulations, meaning that drone operators have to maintain visual contact with their drones at all times, SkySpecs’ drones still rely on human beings.

“We basically have a safety officer on the ground,” Ellis explained. The person is there to change the batteries and drive the drone from one turbine to the next.

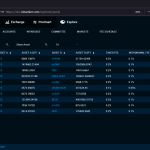

SkySpecs data web portal where customers can navigate through inspection images, review identified damage type, size, and severity, and make decisions on repairs. Credit: SkySpecs.

Since the software instructs the drone when and where to take a photo, according to Ellis no two flight paths are the same, so watching it fly is pretty interesting.

“It’s really kind of fun at a site,” he said. “When you start the drone on one side and you move it to the other side at the same tower, it will choose two different flight paths in those two different inspections because it’s constantly optimizing for the shortest path.”

SkySpecs’ drones inspect wind turbine blades, looking for defects and damage from weather and wear. The drones also take complete turbine measurements that the company then correlates to the photos so it can pinpoint exactly where damage is when they find it. As the company matures, it will then be able to track damage over time, for example returning to the same wind farm one year later to see if the damage has gotten worse or stayed the same.

“Then we can come up with a recommendation for how to fix it,” said Ellis.

Data Fatigue

While Nanduri may be correct in that drones can capture defects better than human eyes, humans don’t have the capacity to process all of the data that wind-turbine-inspecting drones can capture.

“If a human doesn’t have a way to process that [data] it’s actually just overwhelming and sometimes a liability,” said Ellis, adding, “Our customers need decisions, they need them quickly.”

Nanduri agrees. “What the customers want is the results of that transformation,” he said, pointing out that drones may be transformational but it’s the services they provide that makes them transformational, not the drone technology itself.

Both SkySpecs and Intel are working to solve the problem of data fatigue. SkySpecs gives customers a report that highlights the most important features that the drone identified.

“We don’t ever just dump data on our customers,” he said.

As years go by, SkySpecs anticipates the ability to compare photos over time to gain a deeper understanding of how turbine blades age.

“Then we can apply analytics and image processing and these other computational methods to the data,” Ellis said. “[So that] we can start to standardize and have a deeper understanding of how everything is connected,” he added.

Ellis said that SkySpecs’ main focus is data, in particular how blade health affects the total power output of the turbine.

“When you look at your annual energy production, how it is affected by different types of damage?” he asked. The company is looking at leading edge erosion and lightning strikes and other types of wear and tear from different weather conditions. “It’s all about getting to that decision point,” said Ellis.

Can We All Agree on the Problem?

Ellis and Nanduri are both clear that drone-powered inspections are in their infancy. Each expert points to the needs for standards.

“There are no standards,” said Nanduro, arguing that once humans have agreed on the correct classification of a problem, then “the computer vision and machine learning aspects can apply.”

Ellis cites the same problem.

“It’s interesting to us…the different people we work with they all have a different scale of what damage is and which damage is important and they really don’t agree at all,” he said. For example, some of his clients believe that leading-edge erosion should be repaired right away.

“And others say let’s let it go for 5 years and see what happens,” he said. SkySpecs is hoping that its work with the industry will help arrive at some of those standard classifications of damage and when repairs are needed.

“We want to be able to bring a better understanding with our data in what should be done in those scenarios.”

A Whole New Business Process

As drone technology and data analytics mature, it’s clear that a transformation in the process of asset management is inevitable. According to Ellis drones are not a replacement technology but rather “an entirely new way of looking at how to maintain your blade.”

Through its work, SkySpecs is helping to create new standards that can apply to how a blade is manufactured in the first place. “We are also fitting in with how a blade is made and what are the standards to fix it,” he said. “We’re finding data that the industry has never had before.”

Nanduri believes that days of putting new technology on the market and letting it take off on itself are over. “Now you have to show the solution,” he said, “because that is what will lead to the business transformation.”

Phil Christensen of Bentley Systems envisions a day when offshore wind farms have a hanger for a drone and at set intervals (perhaps daily, monthly or quarterly) that drone will fly around the turbines and capture data, which it will then transmit back to the base for analysis — no human intervention at all.

For SkySpecs the focus now is on capturing as much data as possible and using it to find insights that can help the industry.

“For us it’s about standardizing that data collection and making sure that that the quality of that data is the same every single time,” said Ellis. “That’s what a robotic solution enables us. You know if it’s not robotic, it becomes really challenging,” he said.