By Eric Mack,

The supermaterial graphene has been receiving quite a bit of attention over the past few years. The latest breakthrough comes in the form of a method for using the strong, super-conducting one-atom-thick layer of carbon atoms to create two-dimensional materials that could, in turn, be used in the next generation of lasers, electronics and sensors.

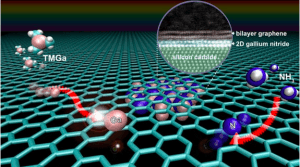

Materials scientists at Pennsylvania State University synthesized two-dimensional gallium nitride for the first time ever using a graphene encapsulation, lending the material’s superb electronic properties and strength to the resulting flat gallium nitride.

Three-dimensional gallium nitride is what’s known as a wide-bandgap semiconductor that can allow devices to operate at much higher voltages, frequencies or temperatures than conventional semiconductors. By growing gallium nitride in a two-dimensional form with the help of graphene, the flattening of the structure essentially transforms it into an ultra wide-bandgap semiconductor with even more supercharged capabilities.

The researchers say that growing the two-dimensional semiconductors effectively triples the energy spectrum they can operate in. The graphene-coated flat material can work within the entire ultraviolet, visible and infrafed spectrum, making it an exciting candidate for new uses in lasers and other electrical-optical devices that manipulate or transmit light.

“We have this palette of naturally occurring 2D materials … But to expand beyond this, we have to synthesize materials that do not exist in nature,” said Zak Al Balushi, a Ph.D. candidate and lead author of a research paper published online in the journal Nature Materials. “Typically, new material systems are highly unstable. But our growth method, called Migration Enhanced Encapsulated Growth (MEEG), uses a layer of graphene to assist the growth and stabilize a robust structure of 2D gallium nitride.”

The researchers used a process to grow graphene using a substrate of silicon carbide that creates a perfectly smooth surface when it meets with another material.

“It’s the key,” explains Joshua Robinson, associate professor of materials science and engineering. “If you try to grow these materials the traditional way, on silicon carbide, you normally just form islands. It doesn’t grow in nice layers.”

Gallium atoms are added that nestle themselves in between two layers of graphene, and then nitrogen is added to initiate the chemical reaction that creates ultra-thin sheets of gallium nitride encapsulated in graphene.

The researchers say that in addition to the exquisite thinness of the material, the process also changes its crystal structure, which could also lead to new applications in electronics.

The finding adds to a growing list of ways graphene could affect various industries, including better batteries, dental fillings, microphones and even bike tires.